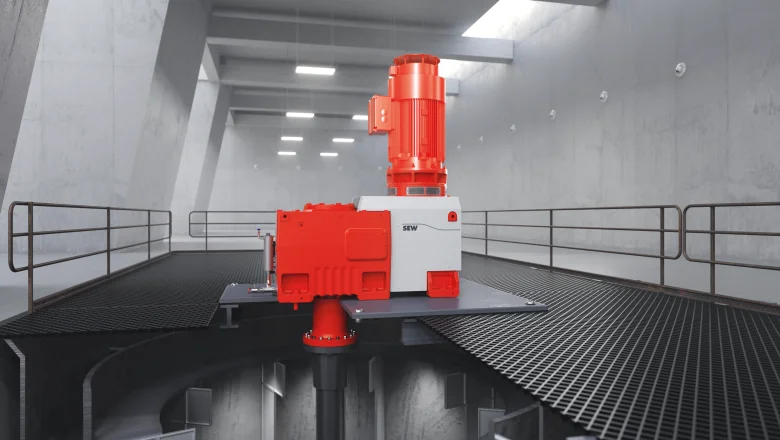

Stirring is a diverse process step in milk production. It must be carried out gently, homogeneously and as efficiently as possible. At the same time, the agitator must be gentle on sensitive components and ensure efficient mixing.

Your requirements

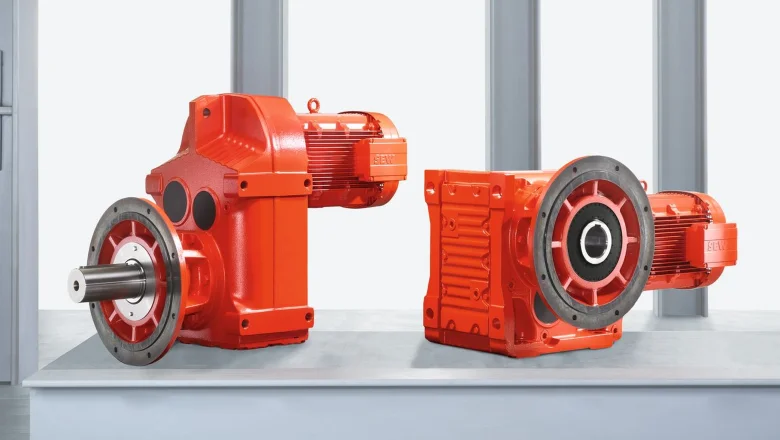

- Scalable, optimized gear units

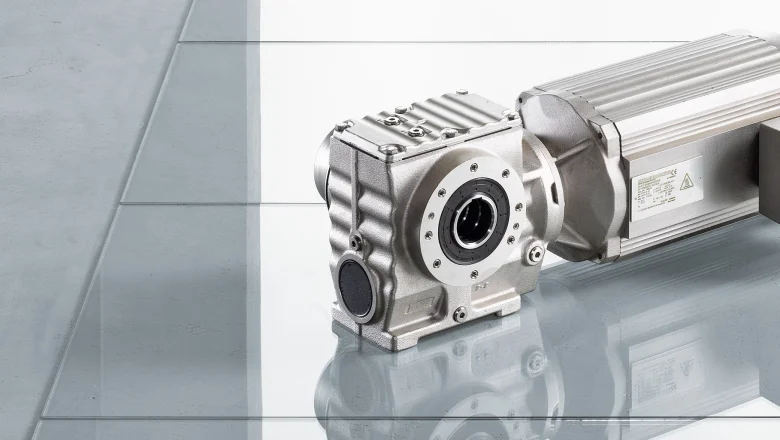

- Stainless steel drive mechanism for the highest hygiene and cleanability requirements

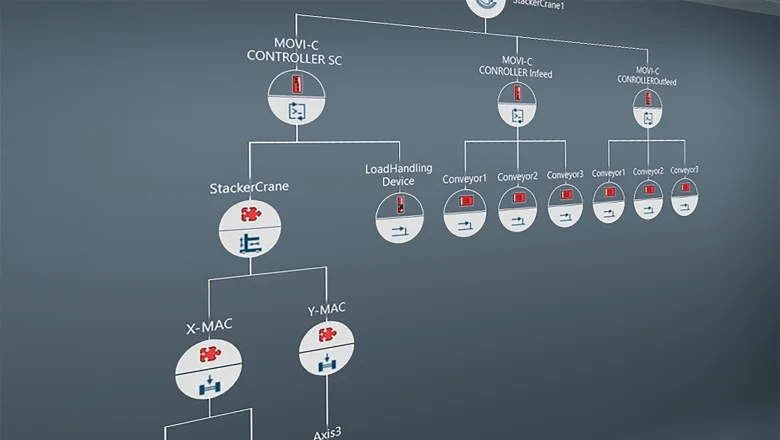

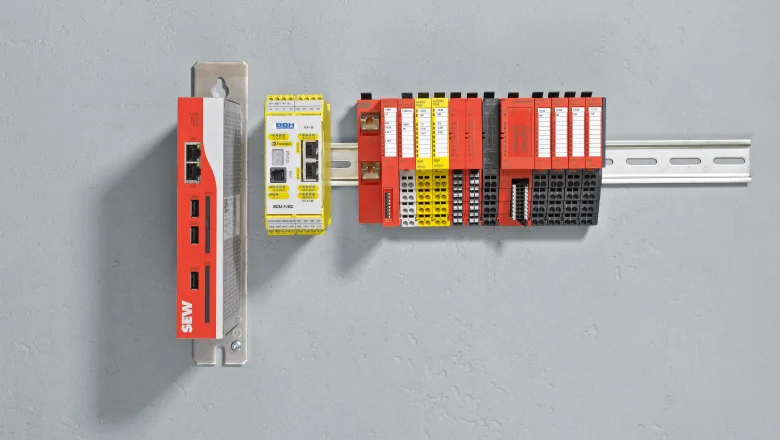

- Compact, simple drive electronics with flexible control from binary to fieldbus connection

- High overload capacity and permitted overhung loads

- Robust, durable technology