In confectionery production, it is important to enhance the value of cooked masses search as jelly, hard and chewy candy masses are of great importance due to the addition of dyes, flavors or acids. The process requirements for the production of confectionery are high. These machines are usually integrated into higher-level control systems. The machines must precisely dose, mix and pour while meeting the highest hygiene standards.

Your requirements

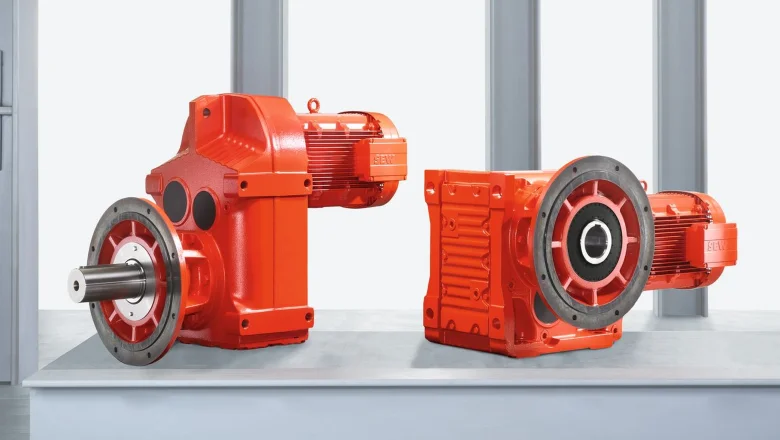

- Durable machines

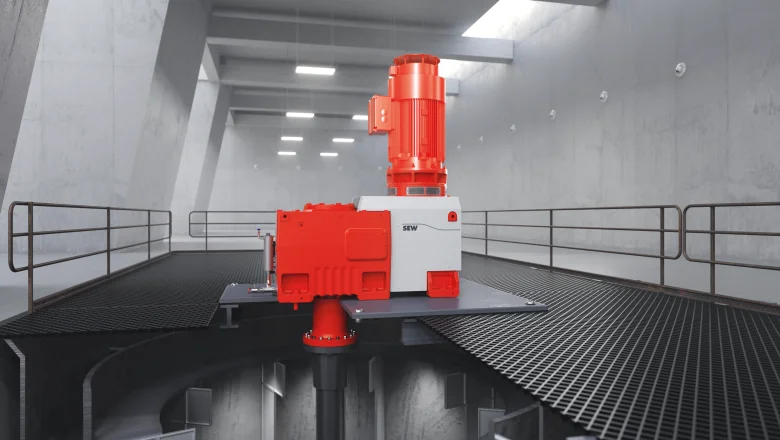

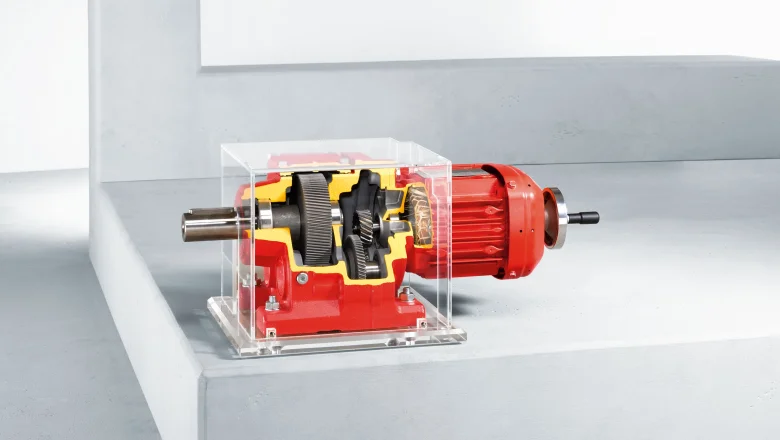

- Robust drive technology

- Easy cleaning

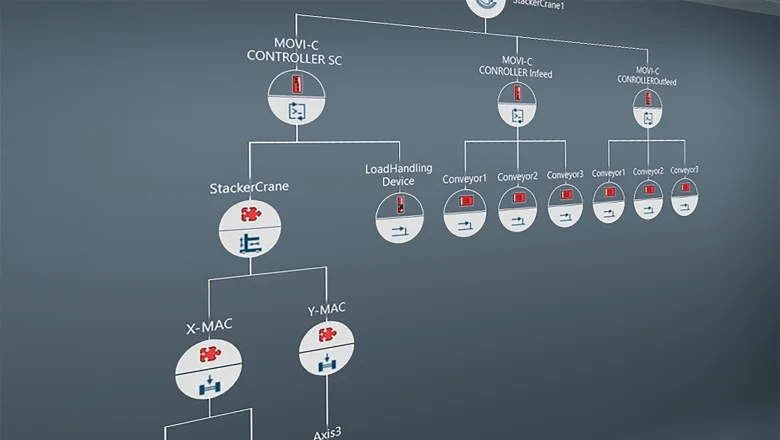

- Future-oriented digitization, monitoring and networking

- Seamless traceability