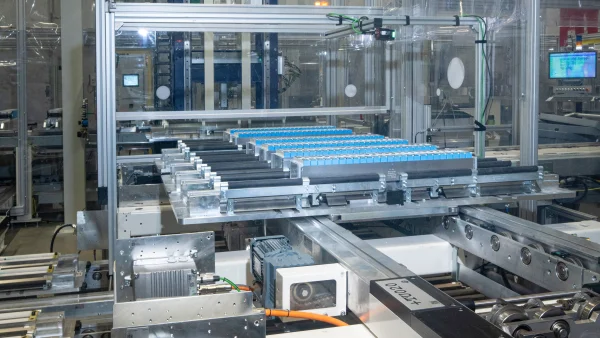

Use of MOVI-C® in battery module production at the BMW Group

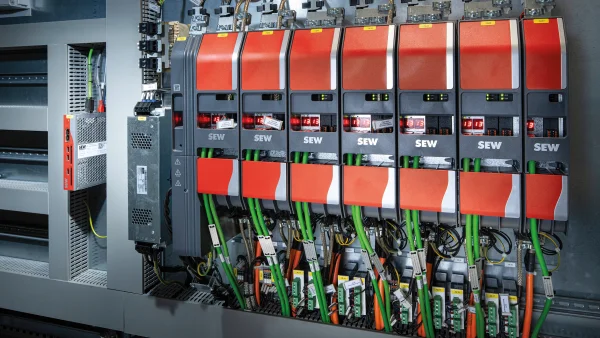

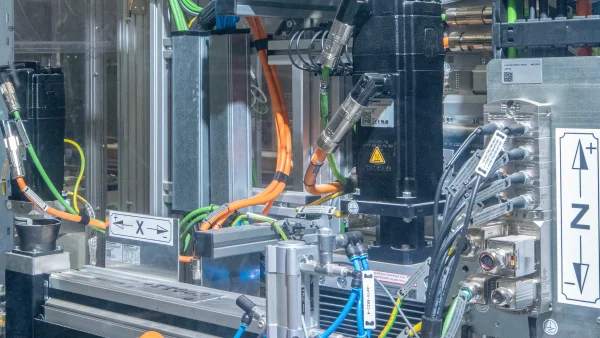

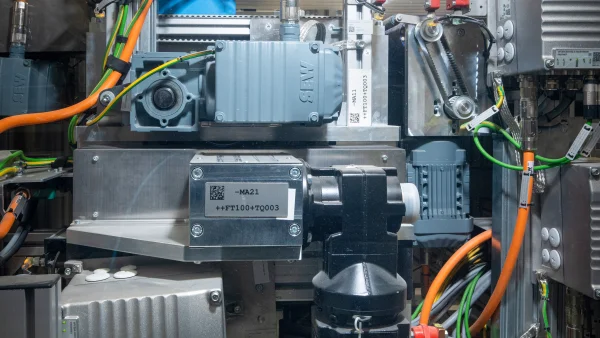

The ultimate standards are required in the premier league of the automotive industry. SEW-EURODRIVE has now supplied the automotive group with drive technology for a battery module production line at the BMW Group plant in Leipzig, which includes all the relevant process steps: Cell preparation, single and double module assembly, adhesive application and welding, curing process, contacting, final assembly, and end-of-line testing.